Custom silicone product manufacturer

CUSTOM SILICONE PRODUCTS FROM SKETCH TO FINISHED PART.

On demand From Concept to Completion: Your Custom Silicone Manufacturing Partner

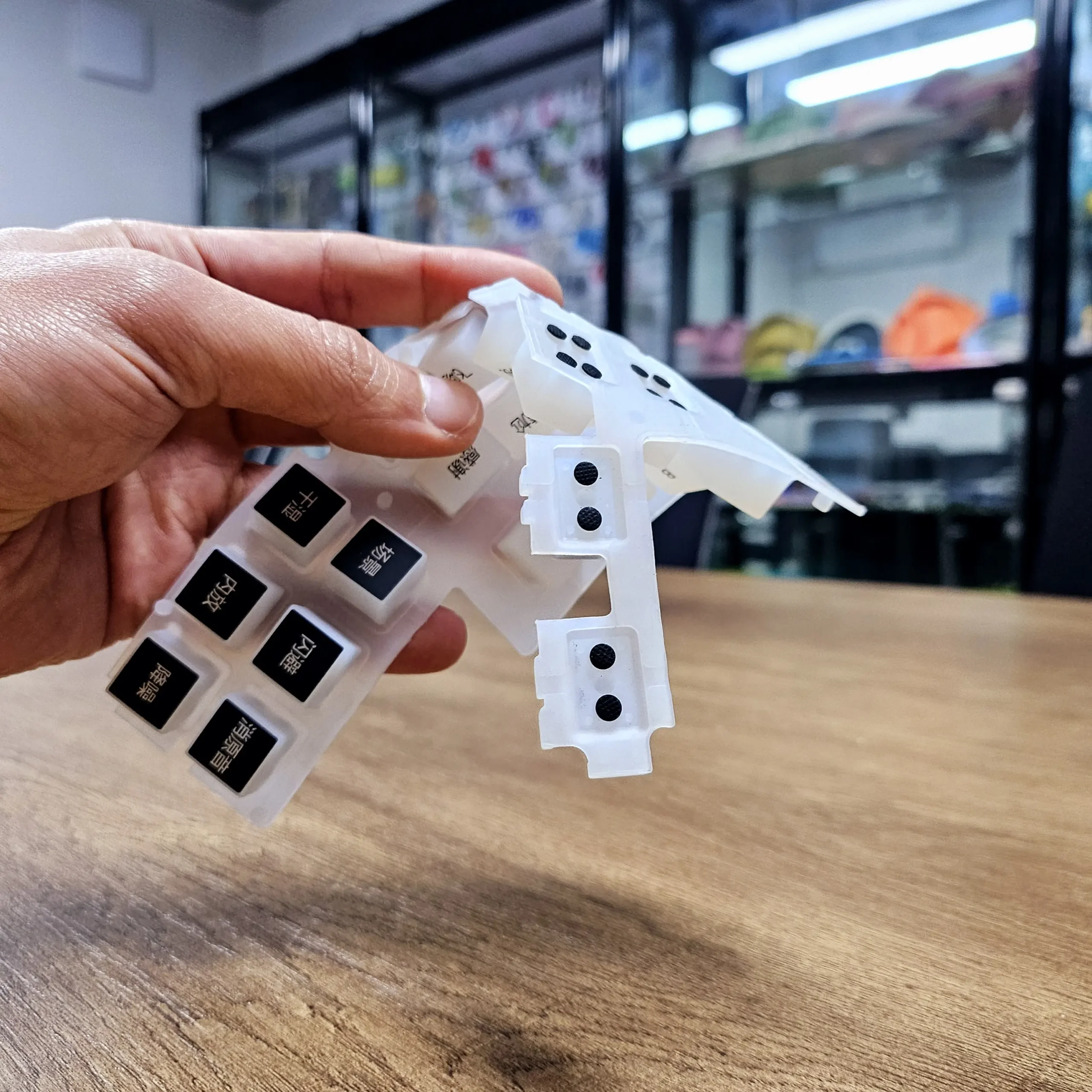

- Soft Tooling: Rapid Prototyping

- Engineering Support: Material selection, design optimization

- Supply Chain Management: Quality, punctuality

ARE INCONSISTENT SILICONE PARTS HURTING YOUR PRODUCTION?

- Missed Tolerances: Parts that don’t fit, leading to assembly delays and rework costs.

- Unreliable Material Quality: Unexpected failures and product recalls due to subpar silicone.

- Poor Communication & Support: Delays in getting answers and resolving problems.

- Unpredictable Deliveries: Production schedules thrown off by late shipments.

QUALITY ASSURANCE FROM A MANUFACTURER WHO GETS IT

- Achieve tolerances as tight as ± 0.2

- Robust documentation and process validation

- High-quality base materials from reputable suppliers

- Material traceability

- Dedicated customer service team

- Technical expertise for product development

- Full support from sketch to production

- Regular production schedules

- On-time delivery

How It Works: From Design to Custom Silicone Parts

We partner with brands and individuals to turn concepts into precise silicone components. Here is how the process works from first contact to finished product.

1. Design Input

Every project begins with a clear understanding of the part’s function and requirements. Our engineering team reviews your files within 24 hours and confirms the next steps.

- CAD files (STEP, IGES, STL)

- 2D drawings with key dimensions

- Material requirements

- Surface / texture specifications

- Color requirements

- Functional and use-case info

2. DFM Review

We evaluate your design for silicone manufacturability. If adjustments are recommended, they are documented and confirmed to ensure tooling accuracy.

- Wall thickness and draft analysis

- Parting line, vent, and gate planning

- Shrink rate considerations

- Tooling feasibility checks

- Risk points and suggested improvements

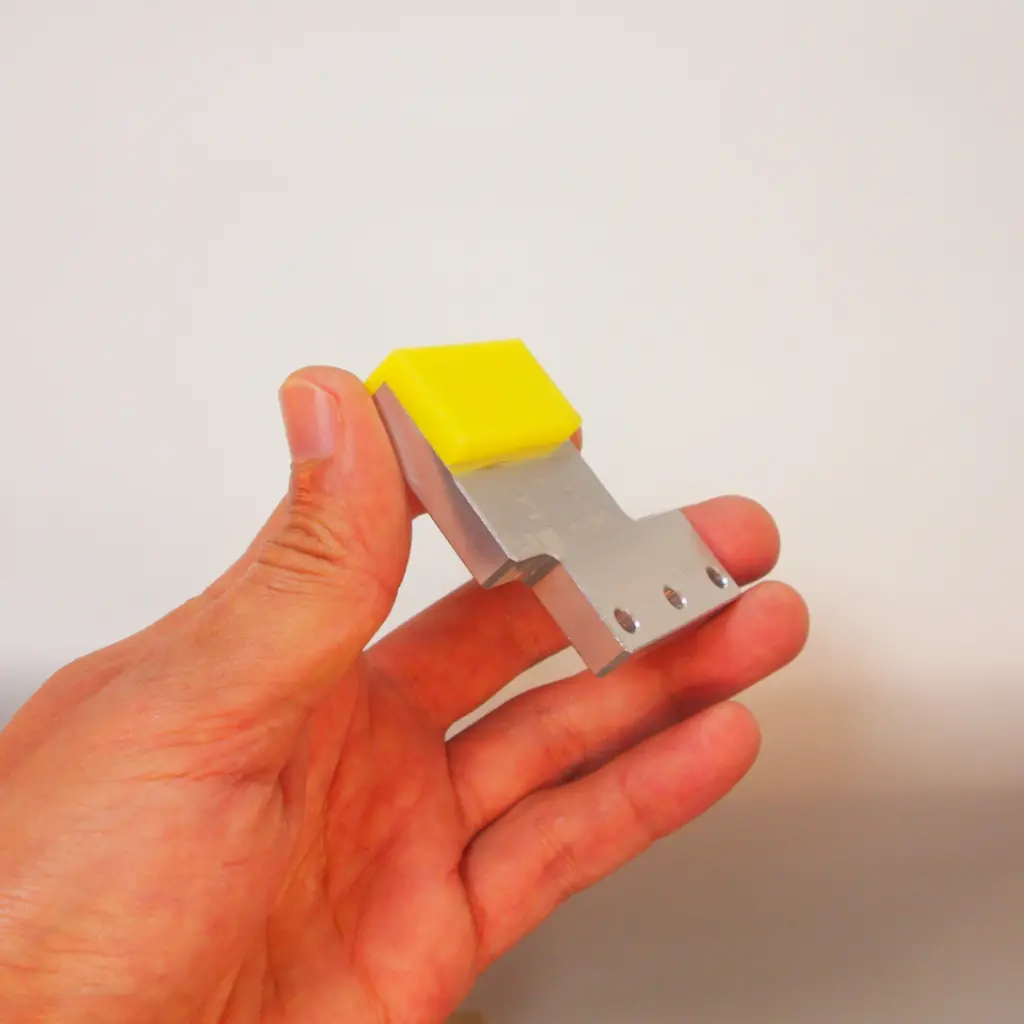

3. Tooling (Mold Fabrication)

Once the design is approved, we build precision tooling using CNC machining or EDM. Every mold is checked against the CAD model before sampling begins.

- CNC-machined aluminum or steel molds

- EDM for fine or complex features

- Surface finishing to required texture

- Dimensional verification

4. Molding & Quality Control

Production begins with validated tooling. Each batch is monitored for consistency, and every shipment passes dimensional and cosmetic inspection before release.

- Silicone compounds mixed to spec

- Molding at set temperature/pressure

- QC checks for dimensions, defects, hardness

- Packing, labeling, and shipping

Why Clients Trust Us With Their Silicone Projects

Our commitment to confidentiality means we don’t publicly disclose our clients’ names or images. This is part of the valuable feedback we consistently receive:

“Dabojin helped us get from first sketch to validated silicone parts in weeks, not months.”

Kate M. – Product Manager, MedTech Startup

“Tolerance control and documentation from Dabojin made our regulatory approval much easier.”

Callum R. – Lead Engineer, Bio-Engineering Firm

“Reliable lead times and consistent quality. We finally have a silicone partner we trust.”

Kayla S. – Operations Director, Consumer Brand

“From DFM to small-batch samples, the Dabojin team was responsive and technically solid.”

Sergio T. – Founder, Robotics Company

“Material traceability and QC reports give our customers confidence in every batch.”

Lena W. – Quality Manager, Industrial OEM

“Communication is clear, honest, and fast. Problems are solved before they reach production.”

Daniel K. – Purchasing, Automotive Supplier

20 YEARS IN CUSTOM SILICONE MANUFACTURING

We turn your product ideas into reality. From the first drawing to the final delivery, we handle everything in-house.

How We Make It

We use the right method for your specific product needs.

- Compression molding

- Liquid injection molding

- Extrusion molding

- Over-molding

Industries We Serve

From everyday applications like intercom cases and toys to advanced sectors such as automotive, electronics, and laboratory equipment, we create solutions for every sector.